- 0800 056 0404

- 0191 386 5303

- sales@opuscnc.co.uk

- Units 22A-D Roeburn House, Mandale Business Park, Durham. DH1 1TH

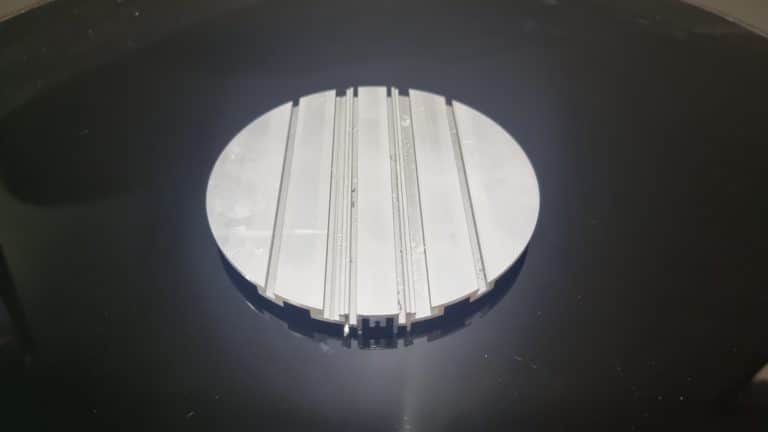

Cutting Aluminium

Cutting Aluminium on a CNC router

Aluminium is a soft metal. With the correct tooling and procedures, our CNC machines are more than capable of cutting aluminium cleanly and precisely.

Known as a soft sticky metal, aluminium needs lubrication to ensure a high-quality finish.

Lubrication

Having a lubrication system in place firstly prevents your tool from overheating and secondly, it stops the soft metal from sticking to your tooling. The lubrication system can be manual or automatic. We recommend the automatic lubricating system if aluminium is to going to be the main material being cut on the CNC machine.

General Tips

- Lubrication is a must on any CNC machine when cutting aluminium regularly.

- Use the correct tool specific for aluminium. On a CNC machine, a dry cut tool can be used if you are cutting aluminium infrequently.

- Slowing down the spindle speed will improve the overall cut and finish.

- Setting the correct feed rate for the tool and the material will improve the cut and help keep the lifespan of the tool.

- Smaller pass depths than standard materials such as wood and plastics will give less stress to the tool. By ensuring smaller passes reduces the risk of tool breakage and material moving.

- Lubrication is a must on any CNC machine when cutting aluminium regularly.

- Use the correct tool specific for aluminium. On a CNC machine, a dry cut tool can be used if you are cutting aluminium infrequently.

- Slowing down the spindle speed will improve the overall cut and finish.

- Setting the correct feed rate for the tool and the material will improve the cut and help keep the lifespan of the tool.

- Smaller pass depths than standard materials such as wood and plastics will give less stress to the tool. By ensuring smaller passes reduces the risk of tool breakage and material moving.